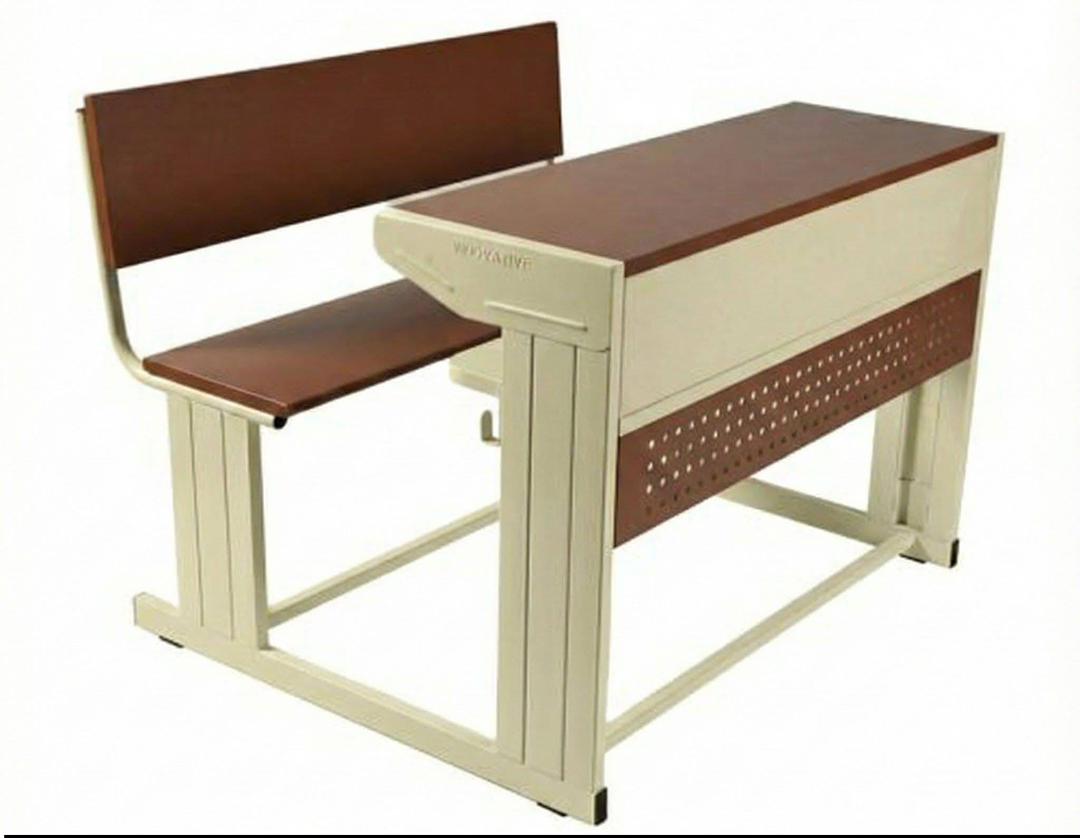

The government has announced plans to procure two million steel dual desks as part of efforts to improve learning conditions across the country, particularly in rural communities where some pupils still study on bare floors. In addition, the government intends to construct 600 new schools nationwide, made up of 200 secondary schools, 200 primary schools, and 200 junior high schools.

The initiative has been widely welcomed as a major step toward improving access to quality education and restoring dignity to the learning environment for thousands of Ghanaian children. Better furniture and new school infrastructure are expected to reduce overcrowding, enhance comfort, and support effective teaching and learning.

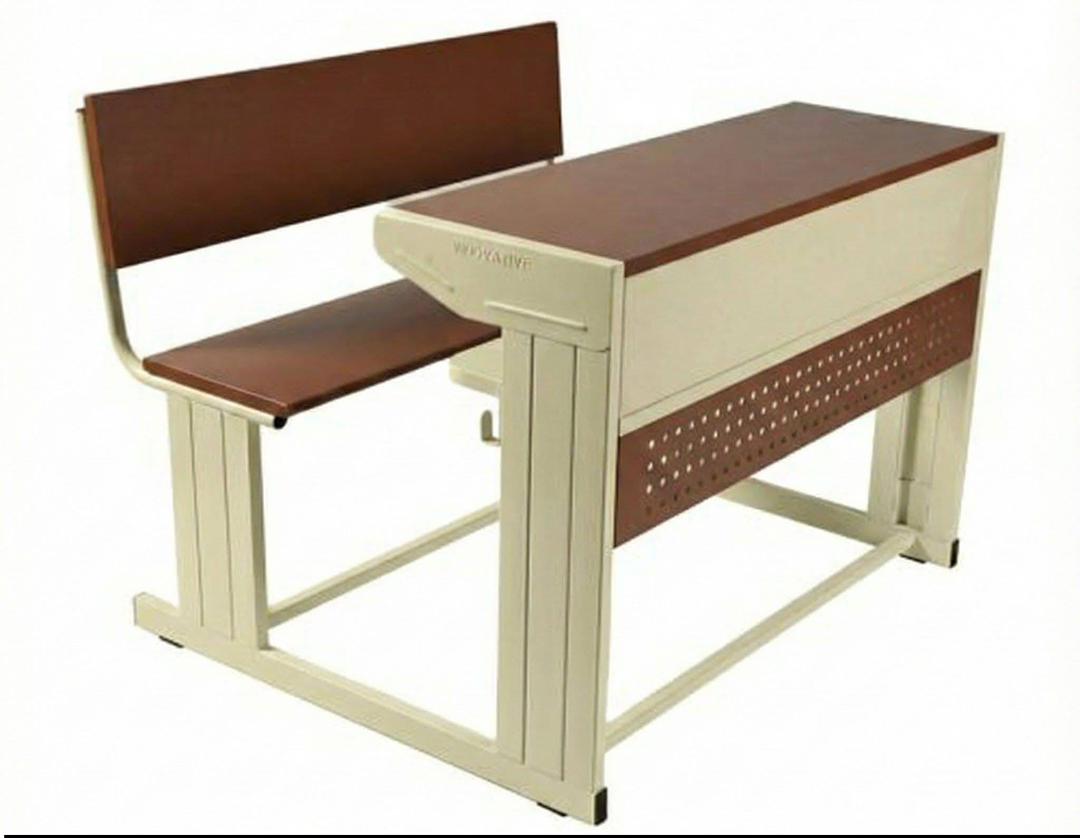

However, the announcement has also sparked an important conversation around local industrial participation. Many believe the desk procurement presents an opportunity to create jobs for Ghanaians if production is done locally rather than through imports. By bringing together skilled Ghanaian artisans, welders, and fabricators into a structured company or consortium, the government could stimulate local manufacturing while meeting national demand.

However, the announcement has also sparked an important conversation around local industrial participation. Many believe the desk procurement presents an opportunity to create jobs for Ghanaians if production is done locally rather than through imports. By bringing together skilled Ghanaian artisans, welders, and fabricators into a structured company or consortium, the government could stimulate local manufacturing while meeting national demand.

Producing the desks locally would not only reduce foreign exchange losses but also build capacity in the metal and furniture industries, encourage skills transfer, and strengthen small- and medium-scale enterprises. With the right standards and oversight, locally made desks could match imported alternatives in both quality and durability.

As Ghana pushes forward with educational reforms and infrastructure expansion, aligning public procurement with job creation and local content policies could ensure that the benefits of such large-scale investments are felt across the wider economy—not just in classrooms, but also in workshops and communities nationwide.